The speed of global business has increased dramatically over the past 20 years, as the internet, telecommunications, and international companies have increased the constant connection between diverse markets. Over the past 2 years, the chemical industry in particular experienced another surge, as the race to create and supply a vaccine for the COVID-19 pandemic pushed many research companies into an even higher gear of development.

Companies need to move and react more quickly and proactively than ever before in history as their chemical needs are faced with increasing pressures: record demand for chemicals in industries ranging from pharmaceuticals to foodstuffs, supply chains strained by COVID-19 with no end in sight, and old avenues for chemical sourcing strained or disappeared entirely. These challenges all make it increasingly important to have stable yet reactive practices to counteract market disruptions and mitigate ongoing risks.

COVID’s Impact on the Chemical Industry

The global pandemic had a massive effect on the world’s economy, and the chemical industry was no exception. Many companies across the industry are still reeling from the COVID Disruption. From the very start of the pandemic, the chemical industry saw a downturn, with a 2.5% decrease in total production as far back as of February 2020 (1.). Some sectors were hit even harder than that, with transportation, construction, and petro all seeing a higher decrease as people stayed home and projects were halted. Companies that were able, shifted their production focus to safety and pharmaceuticals, but this created a bottleneck for much-needed chemicals through 2020.

Since then, the market has responded positively, rebounding to pre-pandemic growth rates. While a great resurgence, many companies were not able to weather the early days of the pandemic. The potential for market disruptions still exists, and sourcing raw materials can still present difficulties, with many companies or avenues out of business. Companies need to carefully consider their needs to develop a sourcing approach to gather necessary materials quickly and efficiently.

The Needs of Chemical Procurement Officer

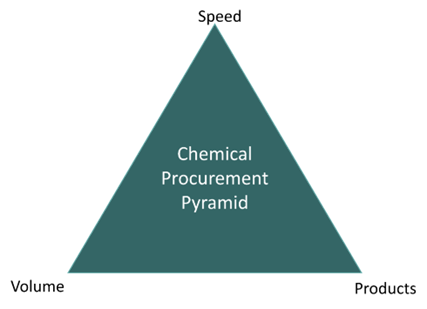

The role of the Chemical procurement officer has become increasingly important, as business operations may become strained by supply-side limitations. While there are no shortage of considerations for procurement officers, their main challenges can be boiled down to:

Volume

- How much of a needed chemical can a given manufacturer provide quickly?

Demand shifts can happen immediately for many companies using chemicals, particularly those in the Contract Research sector. These demands can lead to huge changes in the chemicals needed on a weekly, or even daily basis. Waiting for a manufacturer to scale up can slow or halt new or existing business.

- Solutions

Procurement officers have a couple of ways to counteract this problem. They can

- Work with large-scale providers, who have enough supplies to meet changing needs in their area of focus, or…

- Have a number of smaller manufacturers offering batches of the same product to meet shifting demands.

Both have pros and cons. The first option is much simpler, but prone to disruption if your one supplier hits raw material challenges. The second option is significantly more work to manage but has built-in redundancies in case of market disruptions.

Products

- How much access do you have to the various different chemicals you may need?

Reliable sourcing for a single product isn’t enough. Procurement officers must be able to quickly find any needed chemicals for a new project. This requires companies to have one stable manufacturer that provides many different chemicals (which can be difficult to find and engender a relationship with, plus catastrophic if something fails) or have access to a large stable of individual producers (very time and resource-intensive if managed independently).

- Solutions

Developing a network of reliable producers around the world provides protection from disruptions, as well as benefits for distribution and access. Having a partner to manage your sourcing pipeline for you can mitigate the challenges and resources needed to maintain an effective network like this.

Speed

- How quickly can the needed materials be delivered?

Having access to materials is all well and good, but isn’t of much benefit if it takes months to receive the materials. If the product comes too slowly to meet the business’ needs, then it’s not a good procurement solution. The more time spent receiving materials, the less time your team can spend using them.

- Solution

The only way to counteract this is to create quick and reactive systems for procurement. Companies need to be able to rapidly find new sources for raw materials if a supplier breaks down, have access to a large range of suppliers as new needs present themselves, and have reliable routes through the already disrupted supply chain.

Conclusion

The solution to the balancing act facing procurement officers every day is to have a reactive, quick, and scalable network of multiple chemical manufacturers to meet sourcing needs. This can be difficult to impossible for a single procurement manager to handle on their own. It is necessary to find partners with existing networks of suppliers to tap into. Accessing established global networks is the easiest and safest way to overcome these daily challenges.

Fortunately, Chemlyte Solutions exists to help. They have existing relationships with thousands of chemical manufacturers across all verticals. This network provides built-in redundancies to ensure that even if one supplier fails, another one can step in to meet demand, quickly and efficiently.

How Chemlyte Can Help

Chemlyte is a chemical sourcing provider, offering first-class tailored services for companies seeking to source and manufacture chemicals in China. Built on decades of industry experience sourcing chemicals in China, we are now focused on overcoming the difficulties facing international companies entering the Chinese market.

Serving as the link between sourcing departments and chemical manufacturers, we serve as a trusted partner familiar with the challenges facing both sides to access the benefits of the Chinese market while avoiding its difficulties.

Using Chemlyte Solutions as your trusted partner in sourcing chemicals from China can present a whole new world of opportunity for your chemical needs. Contact one of our consultants to discuss how we can work to grow your business.

References